The Duval triangle explained in 3 minutes

Quickly identify transformer faults

Das Duvaldreieck ist eine der bekanntesten Methoden zur Interpretation von DGA-Ergebnissen. Es kann zur Kategorisierung von Transformatorfehlern auf der Grundlage der relativen Mengen von Methan, Acetylen und Ethylen verwendet werden.

Es gibt viele Anleitungen, die meisten davon sind aber länger als nötig. Wir wollen es besser machen. Hier ist also unsere Kurzanleitung für das Duval-Dreieck. In drei Minuten ist man durch, versprochen!

Basics

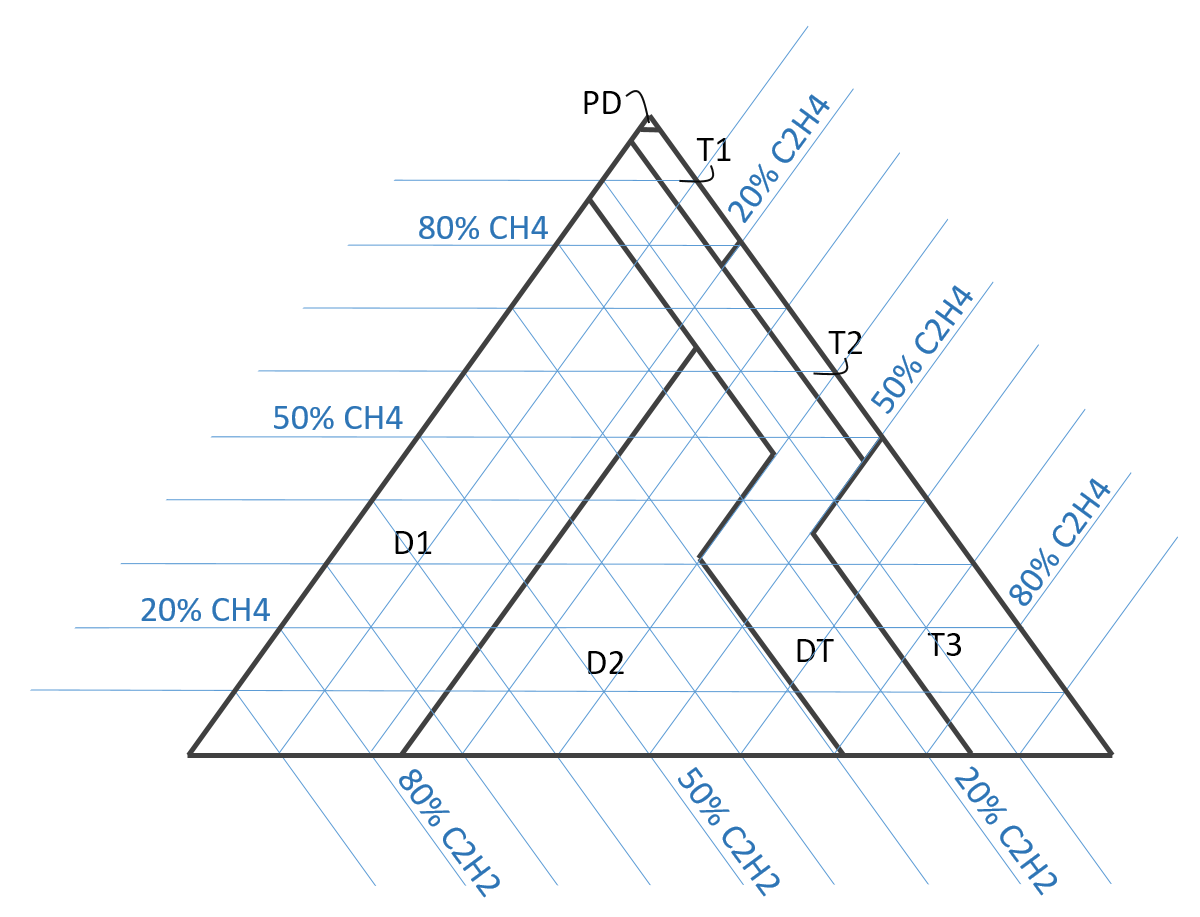

The classification can be done graphically, by printing the following chart on paper.

Then use a ruler to draw a line for the relative amount of each of the three relevant gasses. All three lines should meet at one point.

The location of this point indicates the type of failure.

Example Case

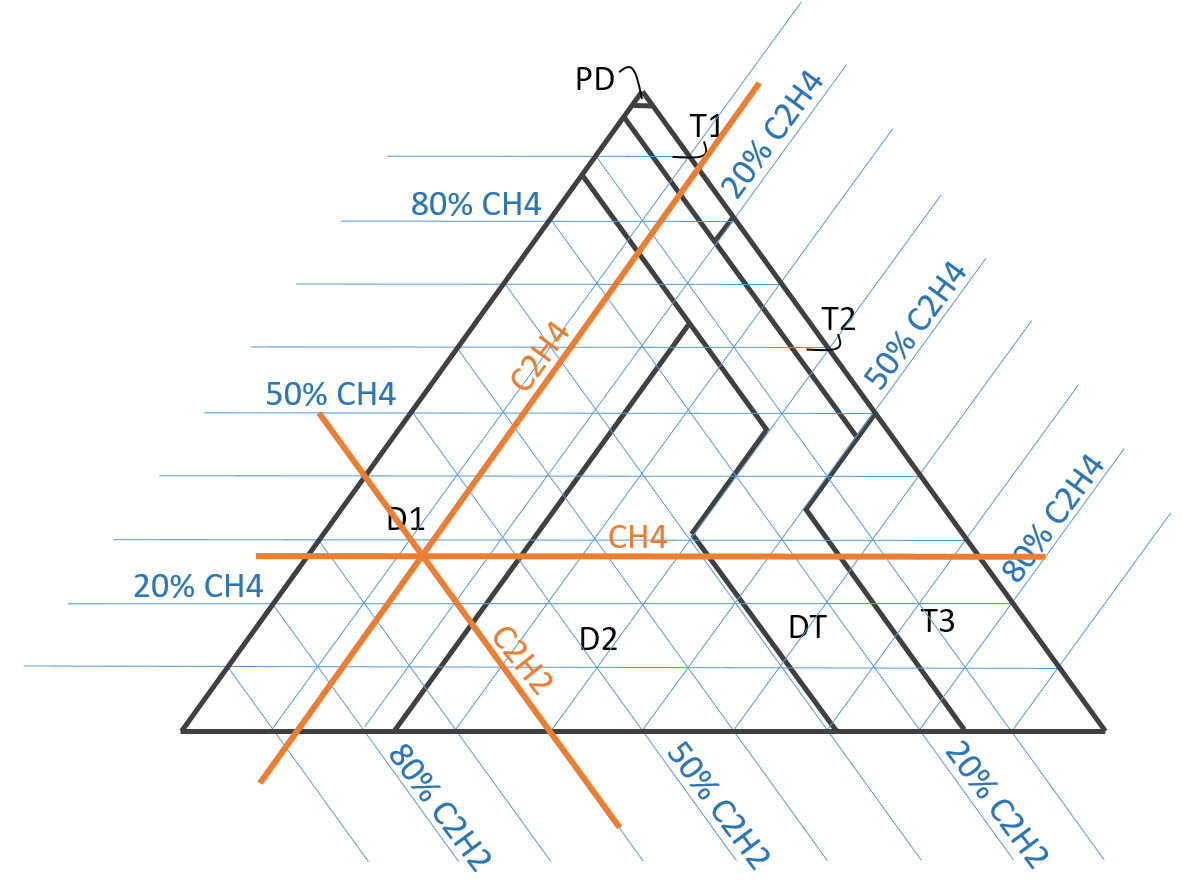

Let's do an example. From a lab measurement we get the following DGA values:

- H2: 8 ppm

- CH4: 1313 ppm

- C2H2: 2908 ppm

- C2H4: 616 ppm

- C2H6: 420 ppm

- CO: 450 ppm

- CO2: 1069 ppm

We only need the values of C2H2, CH4 and C2H4. The other values are not used in the Duval triangle method.

Example Calculation

The percentage of C2H2 is 2908/(2908 + 1313 + 616) = 0.601 = 60.1%.

The percentage of CH4 is 1313/(2908 + 1313 + 616) = 0.271 = 27.1%.

The percentage of C2H4 is 616/(2908 + 1313 + 616) = 0.127 = 12.7%.

The corresponding lines are drawn parallel to the labelling of the axes.

The point of intersection lies in the area called D1, meaning low energy discharge, or sparking.

Failure Codes

The complete list of failures codes can be seen here:

- PD: partial discharge

- T1: thermal fault below 300 degrees celcius

- T2: thermal fault between 300 and 700 degrees celcius

- T3: thermal fault above 700 degrees celcius

- D1: low energy discharge (sparking)

- D2: high energy discharge (arcing)

- DT: mixture of thermal and electrical faults

Note how every possible combination of DGA values will result in a failure classification. There is no area designated as normal.

The duval triangle can only be used for fault classification, but not for fault detection. In other words: Before doing any of this, be sure that your transformer is actually faulty.